Hanbury Autogil builds fastest PPE machine during covid-19 fight

Top engineering firm Hanbury-Autogil has joined forces with packaging giants PFF to create protective equipment on a mammoth scale. With huge production targets to meet PFF turned to the Devon-based engineers and designers in an effort to increase their output of protective aprons.

PFF was using imported industry-standard machines but needed to step up their game to meeting huge production demands. Hanbury-Autogil was commissioned to design and build two bespoke converting machines.

The Hanbury-Autogil team applied their extensive experience in material handling and design to create a machine that is on target to be one of the world’s fastest.

The ground-breaking, roll to roll Apron converting line, which can produce millions of aprons a week, is now being installed at PFF’s factory in Washington, Tyne and Wear. This has created 250 jobs for the duration of the contract that has ramped up to 24-hour production.

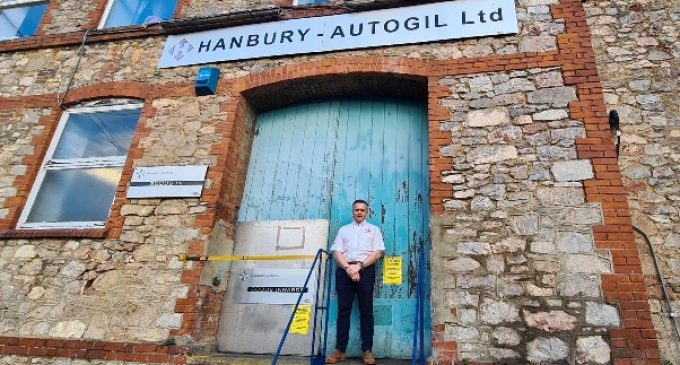

Robert Hanbury (pictured), Managing Director of UK machine builder Hanbury-Autogil, is proud to be part of this project. He said: “PFF approached Hanbury-Autogil with a challenge. We established that the business was seeking apron manufacturing machines that had a faster output than the industry standard versions that they were using.

“The team at Hanbury-Autogil showed an incredible work ethic that led to design a machine that is clearly the fastest PPE apron machine in the world. We look forward to collaborating with PFF on future projects.”

The government has expanded its UK PPE supply to more than 58,000 different settings across the country. The Department of Health and Social Care has distributed more than 3.5 billion PPE items for use by health and social care services in England.

Kenton Robbins, group managing director of PFF Group, said: “We worked closely with the Department of Health and Social Care on due diligence ahead of our appointment as part of the government’s ‘UK-Make’ initiative to source PPE from Britain. “Demand for PPE has soared globally, with more than 210 million plastic aprons needed weekly by the NHS.

“In just six months, amidst a pandemic and while continuing to support the UK’s food retail sector through the production and supply of food packaging, we worked in collaboration with the Hanbury-Autogil experts to set up a new capability and capacity to manufacture disposable aprons.

“We have been able to design and build, two innovative, all-British machines that are the fastest and most reliable in the world, enabling us to significantly increase production.”

The PFF Group has invested more than £2 million in custom-built machines to manufacture PPE for frontline NHS staff and social care workers, the first project was to create the world’s fastest apron machine.

PFF is now launching a health arm of its business and is working with Hanbury-Autogil on a face mask production machine project.

Robert Hanbury said: “Often one of the first sectors to suffer during any economic crisis is engineering. But what has happened here is a great example of not only how dynamic and robust Hanbury-Autogil but also how British engineering, and British companies collaborating can join forces to deliver such an amazing machine.”