Robotics and resilience. Futureproof your business with Universal Robots

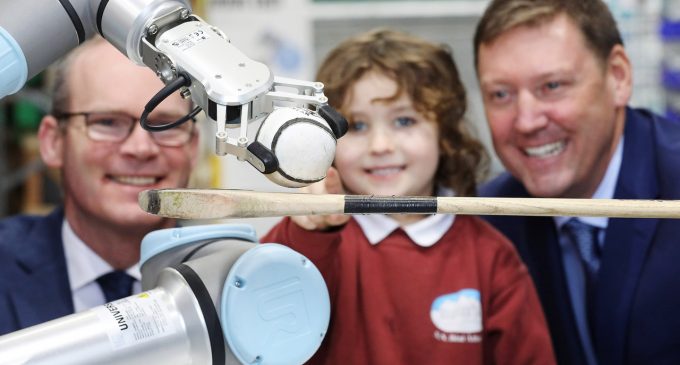

Peter Creighton, Managing Director of Reliance and Tánaiste Simon Coveney. Robots make Tánaiste Simon Coveney’s favourite pizza at Reliance Limerick in January.

From a global labour shortage to the unexpected challenge of the Covid-19 crisis, automation has never been more relevant to the survival of manufacturing businesses.

Universal Robots, the global leader in automation, boasts a ten-year legacy in developing and providing collaborative robots and has a strong footprint in manufacturing across Ireland and the UK.

In response to immediate challenges caused by the Covid-19 pandemic, Universal Robots has created a free online suite of educational tools that can be accessed from home or the office and will support Irish businesses to discover how automation can transform its operations.

The free online suite includes:

- Online meetings

Avail of a 45-minute, one-on-one online meeting with a local member of the Universal Robots team to discuss how collaborative robots could become part of your business.

- Online Academy

Complete easy-to-follow modules to upskill in automation and receive an official certification on completion.

- Webinars

Experience how Universal Robots cobots perform various functions and how your business can benefit.

Stay in the loop by following Universal Robots A/S on LinkedIn

- Case Studies

Discover the real-life impact cobots are having on businesses across the world.

Following a seismic shift in the perception of automation in the workplace, manufacturing businesses in various sectors such as pharma, electronics, food and construction have transformed their operations by turning to Universal Robots cobots to fulfil dispensing, welding, screwdriving, inspection, finishing and other assembly line tasks.

But how easy is it to integrate a cobot and what real benefits can they offer businesses? Irish Development Lead at Universal Robots, Samantha Cummins-Byrne, explains.

“Bettering business efficiency, increasing profitability and improving employee safety are the primary concerns manufacturing businesses are facing and actively trouble-shooting. We know from our experience with manufacturers that issues such as labour shortages, employee safety and even floor-space can prevent them from competing in this highly-challenging market. “

“Having entered the Irish market in 2015 we’ve made a significant impact in terms of changing the perception of automation and educating businesses here, along with the support of our distribution partners, Reliance Automation and Cobots.ie, and the opening of the first UR cobot training centre in Cork.”

“Our cobots have resolved issues for thousands of manufacturers and the work we’ve done in the last couple of years has brought about hugely positive impacts to the profitability, efficiency and culture of Irish businesses. These results are now the focal or talking point industry-wide.

“Our cobots are the very peak of innovation but also accessible, and it’s this powerful combination that allows businesses of all sizes to be part of the new revolution and build resilience. With current crisis in mind, we’d urge businesses, regardless of size, to get in touch and discover how our tech can give you a competitive edge and safeguard operations for the future.

“Our cobots are extremely cost-effective. Customers experience the financial benefits of their investment in just a couple of months. We offer a leasing programme too to combat cash flow and seasonal fluctuations which is great for SMEs. “

“One of the main attractions to our cobots is how easy they can be programmed. With just basic training, our cobots can be programmed to perform any task in just a couple to hours. Our cobots have. been programmed to complete just about everything – from stacking boxes to slicing pizza to polishing steel. Interestingly, the ease of programming also means that our cobots can be redeployed to different areas as required, supporting peak production times or unexpected staff shortages.

“Consistency is a real draw for businesses who use our cobots. For example, tightening screws or sanding a piece of wood will always be done with the same tension and pressure, removing the risk of human error.

“Our cobots can be situated in small spaces and are intentionally built to interact or collaborate with humans. In-fact, our customers tell us regularly that their human workforce feels motivated and rewarded by the arrival of a cobot as it means they are given. The opportunity to upskill in automation programming, while also no longer having to complete harmful or repetitive tasks.”

For more information visit universal-robots.com or Universal Robots A/S on LinkedIn.