3D cardiovascular models, sustainable buildings, bio-based and self-healing materials define the future of plastics in Valencia

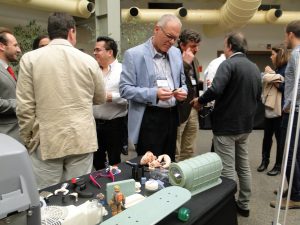

Last week, AIMPLAS brought together in Valencia some of the greatest agents in the international scene in the field of materials innovation. More than 200 professional related to the plastics industry attended the first edition of the seminar Plastics are Future, where they were shown some of the most recent innovations on plastic materials and their applications in sectors such as medicine, electronics, construction and packaging.

Last week, AIMPLAS brought together in Valencia some of the greatest agents in the international scene in the field of materials innovation. More than 200 professional related to the plastics industry attended the first edition of the seminar Plastics are Future, where they were shown some of the most recent innovations on plastic materials and their applications in sectors such as medicine, electronics, construction and packaging.

In terms of eco-efficient architecture, Acciona launched composite innovative façades that allow to make up from insulators or photovoltaic cells to vertical gardens or ventilated façades, while ITMA presented an innovative perspective of architectural textiles. The University of Alicante showed the characteristics of a self-healing new material with intelligent properties, whereas Stratasys informed on additive manufacturing innovations by means of its new 3D printers.

3D printing applied to cardiology

The applications of the new plastic materials in sectors such as medicine have been shown by professionals from the Virgen Macarena – Virgen del Rocío University Hospital, who have already carried out complex cardiovascular interventions successfully, assisted by 3D printed organ models.

As Adolfo Benedito, Materials researcher in AIMPLAS and organizer of the meeting stated, “the innovation in polymers has allowed to obtain new high-performance materials, such as fire-resistant or superhydrophobic materials with anti-icing properties with applications in demanding sectors, such as construction and aeronautics”. Additives and nanomaterials are some of the allies of plastic or polymer materials, which allow giving them new properties until they become what has been called as “intelligent plastics”. Their capability to react to external stimuli and change shape and state gives them a huge advantage with regard to conventional materials.

Derprosa has launched its new film-shaped material used as a packaging coating. Its product Soft Touch has proved the influence of touch and sight in customer’s purchasing decision to the point of causing positive neuronal sensations that lead to buy in a 70 % of the consumers surveyed.

Derprosa has launched its new film-shaped material used as a packaging coating. Its product Soft Touch has proved the influence of touch and sight in customer’s purchasing decision to the point of causing positive neuronal sensations that lead to buy in a 70 % of the consumers surveyed.

Another great research line in the field of polymers shown in this international meeting has been the development of sustainable solutions from renewable, biodegradable or compostable sources with a huge number of applications in sectors such as packaging. The new manufacturing processes and a wrap-up to funding R&D aids and entrepreneurs have been also in the meeting.

The meeting has had the participation of PolyOne, Arkema, Iesmat, Derprosa (Taghleef Industries), Stratasys and Guzmán Global as sponsoring companies.

AIMPLAS, the Plastics Technology Centre is located in Valencia, Spain and is a non-profit research association with the object to operate as a technological partner for enterprises from the plastics industry and thus offering them integral and customized solutions by coordinating research, development and innovation projects as well as technology services (analysis and testing, technical assistance, training as well as competitive and strategic intelligence).